EXPERIMENTAL THERMOCHEMICAL, PHYSICAL AND MECHANICAL CHARACTERIZATION OF THE UNIAXIAL COMPRESSION OF PVC TUBES LOADED WITH 12.54% AND 51.02% OF DURA PALM KERNEL SHELL POWDER

Main Article Content

Abstract

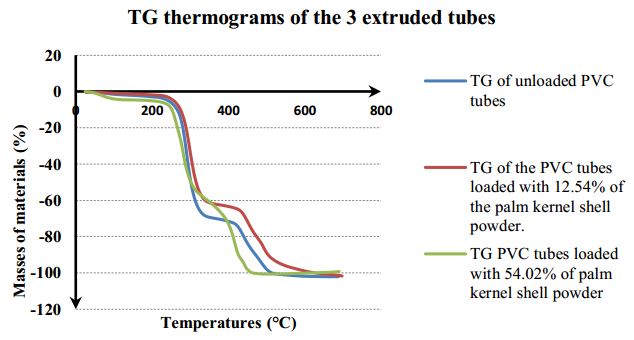

We have carried out here a chemical, thermal, physical characterization and a study of the mechanical behavior to the tubular compression of the PVC tubes loaded with 0%, 12.54% and 51.02% of the dura palm kernel shell powder obtained by extrusion and give an approach on its use. To achieve these objectives, we took the unloaded PVC tubes then the PVC tubes loaded with 12.54% and 51. 02% of the extruded shell powder, which we characterized: thermally by ATG/DSC with a LENSEI apparatus to obtain TG and DSC, chemically by Fourier transform infrared analysis with a Thermo Scientific Nicolet iS5 IR spectrometer to obtain FTIR, physically with standard equipment according to standards to obtain density, then mechanically by uniaxial tubular compression with a machine of compression-flexion of mark controlab to obtain the bearing capacities, the resistances and the behavior of the tubes to the uniaxial tubular compression. We obtained: at elaborated, tubes of diameter (D=90mm and d=82mm) of color light gray, dark gray, dark black respectively for the PVC tubes unloaded and loaded to 12.54% and 51.02%. DSC thermograms of the tubes showed glass transition, combustion temperature, calcination temperature and ash onset temperature and TG thermograms, mass change on dehydration, dehydrochlorination, condensation and residual calcination sensitive. FTIR showed particular groupings of the presence of: lignin from palm kernel shells and chlorine from PVC in the tubes. The density of the tubes gave 1.42 g/cm3 for the unloaded PVC tubes, 1.38 g/cm3 for the loaded PVC tubes at 12.54% and 1.23g/cm3 for 51.02% justifying the low density of the hull powder in the tubes. The bearing capacity as well as the mechanical strength, the shortening and the compression behaviour of the tube allowed to say that the unloaded PVC tubes and those loaded at 12.54% have a tenacious and ductile behaviour while those loaded at 51.02% have a rigid, brittle and fragile behaviour. These results show that the palm kernel shell powders used as loads influence in a sensitive way the physical, thermal, chemical and mechanical properties allowing several fields like aeronautics, automobile, building, toys for entertainment and laboratory materials to be interested in its production.

Article Details

References

han, T., Hameed Sultan, M.T.B. and Hamdan Ariffin, A. (2018) The Challenges of Natural Fiber in Manufacturing, Material Selection, and Technology Application: A Review. Journal of Reinforced Plastics and Composites, 1-10. https://doi.org/10.1177/0731684418756762.

Hammiche, D., Boukerrou, A., Djidjelli, H., Corre, Y. M., Grohens, Y., &Pillin, I. (2013). Hydrothermal ageing of alfa fiber reinforced polyvinylchloride composites. Construction and Building Materials, 47, 293-300. https://doi.org/10.1016/j.conbuildmat.2013.05.078.

Augier, L. (2007). Etude de l’élaboration de matériaux composites PVC/bois à partir de déchets de menuiserie: formulation, caractérisation, durabilité et recyclabilité (Doctoral dissertation). URL: http://ethesis.inp-toulouse.fr/archive/00002291/

Djomi, R., Meva’a, L. J. R., Nganhou, J., Mbobda, G., Njom, A. E., Bampel, Y. D. M., &Tchinda, J. B. S. (2018). Physicochemical and Thermal Characterization of Dura Palm Kernel Powder as a Load for Polymers: Case of Polyvinyl Chloride. Journal of Materials Science and Chemical Engineering, 6(6), 1-18. DOI:10.4236/msce.2018.66001.

Misse, S. E., Obounou, M., Ohandja, L. A., & Caillat, S. (2013). Utilisation des coques de noix de palmiste comme combustible dans un four de fusion de la ferraille. Journal of Renewable Energies, 16(1), 75-89.

Hidayu, A.R., Mohamad, N.F., Matali, S. and Sharifah, A.S.A.K. (2013) Characterization of Activated Carbon Prepared from Oil Palm Empty Fruit Bunch Using BET and FT-IR Techniques. Procedia Engineering, 68, 379-384.

https://doi.org/10.1016/j.proeng.2013.12.195.

Djomi, R., Fokam, C. M., Biyeme, F., Mveh, C. M., Olembé, R., Ntede, H., &Atangana, A. (2021). Industrial Elaboration by Extrusion of PVC Tubes Loaded with Micronized Dura Palm Kernel Shell Powder. Journal of Materials Science and Chemical Engineering, 9(10), 41-69. DOI:10.4236/msce.2021.910004.

Elachaby, F. (2012) Mechanical and Thermal Properties of Polypropylene Reinforced with Alfa Fiber under Different Chemical Treatment. Materials and Design, 35, 318-322. https://doi.org/10.1016/j.matdes.2011.09.023.

Dietsch, P., Franke, S., Franke B., Gamper, A. and Stefan, W. (2014) Methods to Determine Wood Moisture Content and Their Applicability in Monitoring Concepts. Journal of Civil Structural Health Monitoring, 5, 115-127. https://doi.org/10.1007/s13349-014-0082-7.

Dansuk Industrial Ltd. CO. Industral Complex’ HEAD OFFICE: 705, 1DA-SHIHWA.

https://www.thermofisher.com/order/catalog/product/IQLAADGAAGFAHDMAZA.

Elachaby, F. (2012) Mechanical and Thermal Properties of Polypropylene Reinforced with Alfa Fiber under Different Chemical Treatment. Materials and Design, 35, 318-322. https://doi.org/10.1016/j.matdes.2011.09.023.

Zhou, N.T., Yao, L., Liang, Y.Z., Yu, B., Ye, M.Q., Shan, Z.D. and Qiu, Y.P. (2013) Improvement of Mechanical Properties of Ramie/Poly(Lactic Acid) (PLA) Laminated Composites Using a Cyclic Load Pre-Treatment Method. Industrial Crops and Products, 45, 94-99. https://doi.org/10.1016/j.indcrop.2012.12.014.

Chow, C., Xing, X. and Li, R. (2007) Moisture Absorption Studies of Sisal Fibre Reinforced Polypropylene Composites. Composites Science and Technology, 67, 306-319. https://doi.org/10.1016/j.compscitech.2006.08.005.

Nekkaa, S., Guessoum, M., Grillet, A.C. and Haddaoui, N. (2012) Mechanical Properties of Biodegradable Composites Reinforced with Short Spartiumjunceum Fibers before and after Treatments. International Journal of Polymeric Materials and Polymeric Biomaterials, 61, 1021-1034. https://doi.org/10.1080/00914037.2011.617332.

Zhou, N.T., Yao, L., Liang, Y.Z., Yu, B., Ye, M.Q., Shan, Z.D. and Qiu, Y.P. (2013) Improvement of Mechanical Properties of Ramie/Poly(Lactic Acid) (PLA) Laminated Composites Using a Cyclic Load Pre-Treatment Method. Industrial Crops and Products, 45, 94-99. https://doi.org/10.1016/j.indcrop.2012.12.014.

Abu-Sharkh, B.F. and Hamid, H. (2003) Degradation Study of Date Palm Fibre/Polypropylene Composites in Natural and Artificial Weathering: Mechanical and Thermal Analysis. Polymer Degradation and Stability, 85, 967-973. https://doi.org/10.1016/j.polymdegradstab.2003.10.022.

Radhakrishnan Nair, M.N., Thomas George, V. and Gopinathan Nair, M.R. (2007) Thermogravimetric Analysis of PVC/ELNR Blends. Polymer Degradation and Stability, 92, 189-196. https://doi.org/10.1016/j.polymdegradstab.2006.11.014.

Trotignon, J.P., Verdu, J., Dobraczynski, A. and Piperaud, M. (2006) Précis des matières plastiques, Structures propriétés, mise en oeuvre, normalisation. Nathan 2 éd, 231 p.